MACHINE FEATURES

Smartly engineered for efficiency, precision, and ease of operation

Low Manpower

Only 7 operators needed per shift

Energy Efficient

Runs on just 75KW power

Fully Automated

PLC controlled batching & mixing

High Accuracy

Cutting precision ±1mm

Fast Adjustments

Change block size in 30 seconds

Smart Reporting

Auto-generated batch reports

Easy Maintenance

Optimized for simple upkeep

Modular Design

Fully scalable AAC system

TECHNOLOGY AND TRAINING

Complete Training

We train your personnel in recipe preparation, mix design, and the entire AAC production process.

Plant Design & Layout

We help design the AAC plant and layouts using the latest technology to maximize efficiency and output.

Installation & Start-Up Support

Our specialized team of engineers assists you with AAC machinery installation and start-up.

Block Density Flexibility

Training is provided to manufacture AAC blocks in different densities ranging from 400–600 kg/m³.

Technical Know-How & Maintenance

We provide training on equipment maintenance, AAC block machinery handling, and laboratory quality control for raw materials.

BATCHING PLANT

Dosing of Cement in AAC Plant: Automatic

Dosing of Lime in AAC Plant: Automatic

Dosing of Dry Flyash / Pond Ash slurry: Automatic

Dosing of Gypsum in AAC Plant: Automatic

Dosing of Return Slurry in AAC Plant: Automatic

Liquid batching of water in AAC Plant: Automatic

Liquid batching of 2 additives in AAC Plant: Automatic

Batching of Aluminum Powder in AAC Plant: Manual / Automatic

Return slurry preparation in AAC Plant: Automatic

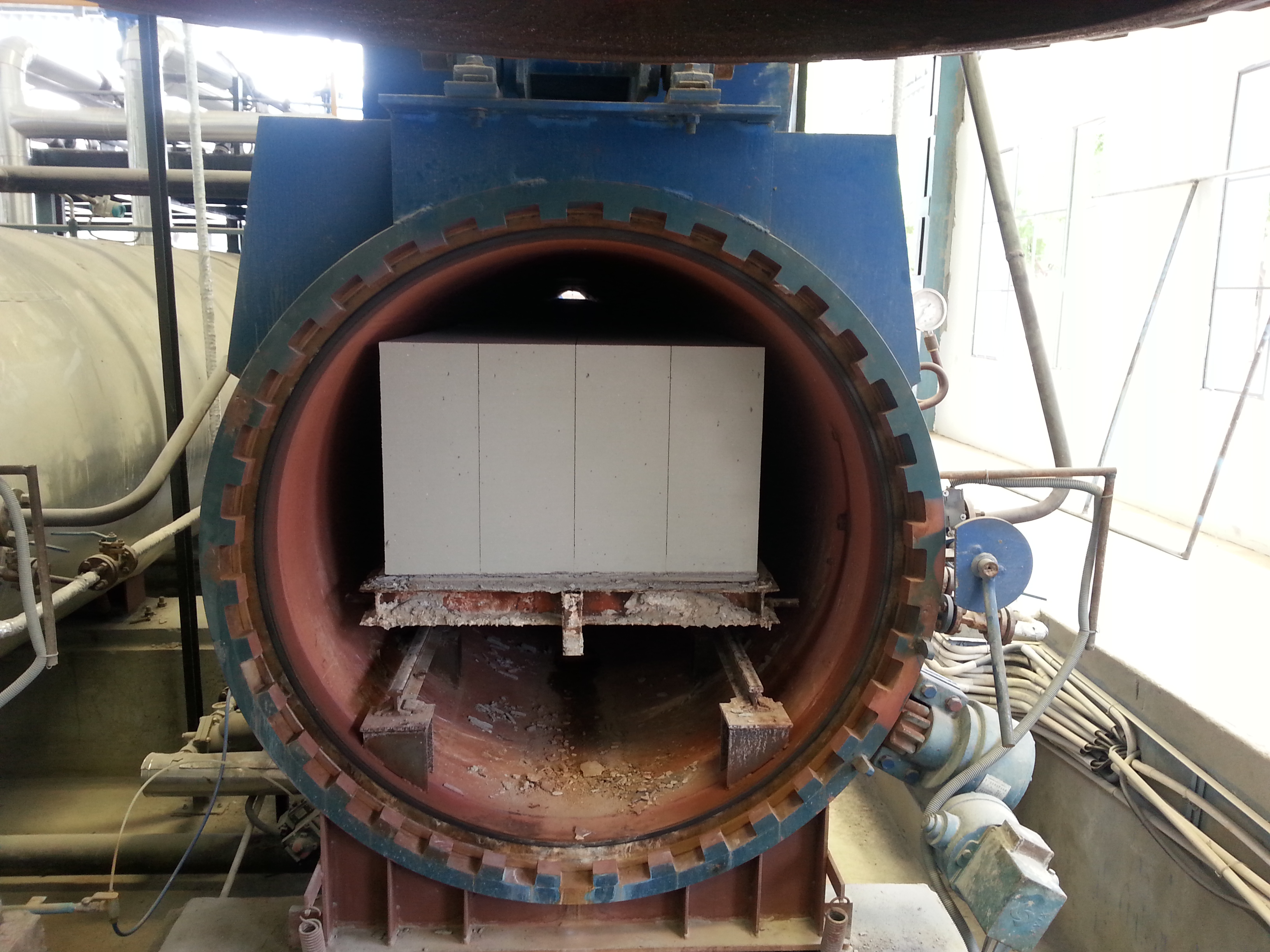

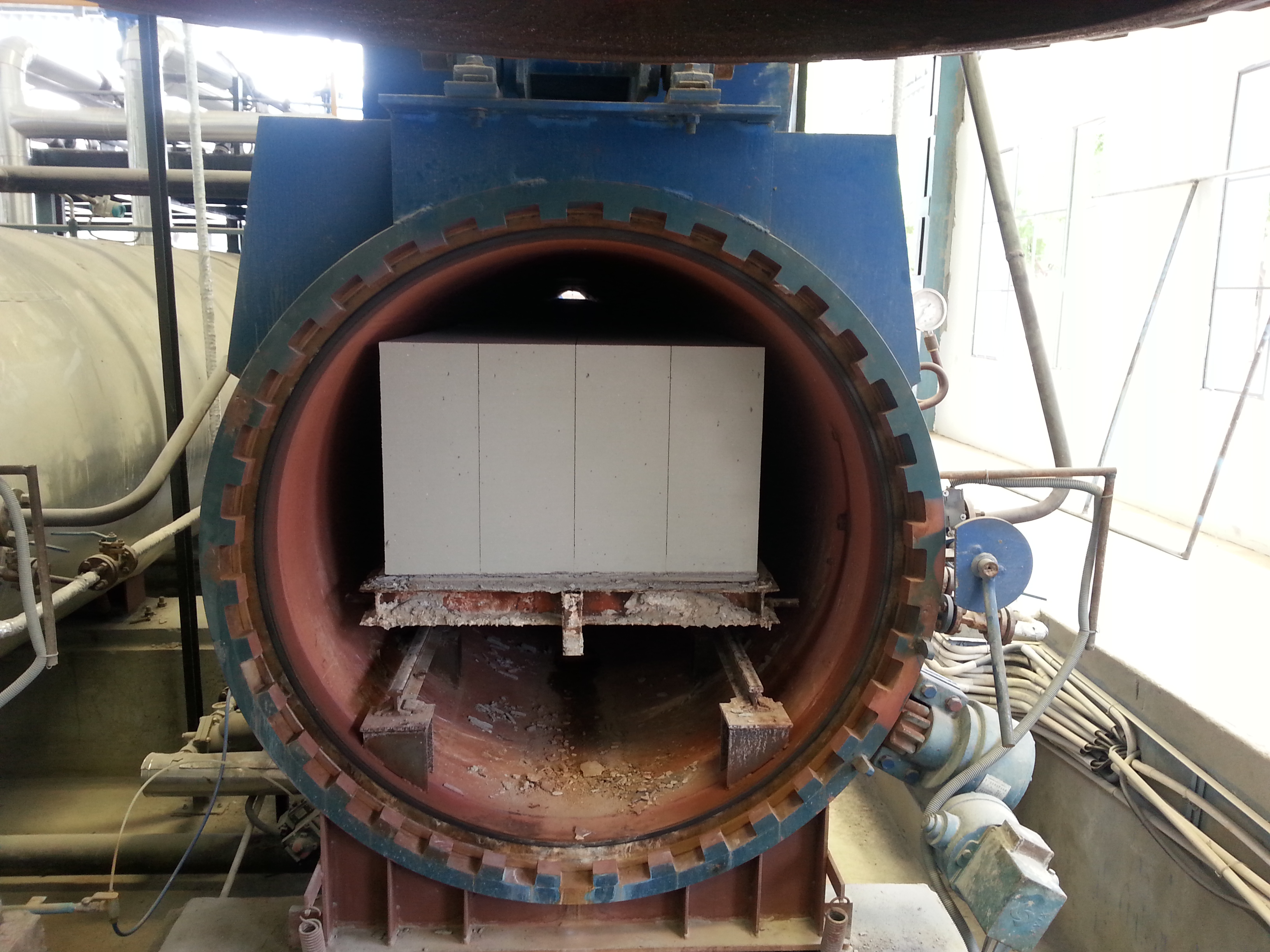

AUTOCLAVING SYSTEM

State of the art autoclaving systems can be designed and offered by us in AAC plant, which provide the user with the following

PLC operation, charging / maintaining / discharging will be carried out using PLC systems and specially designed control valves

We can also offer technology and equipment for heat recovery systems used to recovery the condensate and vent heat from the autoclaves for AAC plants.

Autoclaving will be carried out at 12 bar pressure, 190 degrees

CUTTING MACHINE

Fully automatic, PLC controlled AAC Cutting Machine

Adjustment / Change of size using PLC controller. No need to change position of saw or wires.

Time required to change the size: Less than 30 seconds.

Memory option available to store different sizes.

Accuracy of cutting: +/- 1 mm

Single operator controlled AAC Cutting Machine

Size of Block : 600/650 mm x 200/240mm x 75/100/125/150/200/230 mm

AUTOMATION

Our dedicated team of engineers, automation specialists, designs automation solutions and puts them into use for all industrial applications.

We develop individual solutions for you in the field of process automation. Our range of products also includes visualization systems.

We have specially designed solutions for automation in the field of AAC Blocks Equipment.

Become a Manufacturer:

Now you too can own a local New Age Precast Wall Systems business. New Age precast wall forming equipment is a great business opportunity available for purchase in your area. We offer a system of licensing agreement to use the equipment in a specific geographical area. As part of the licensing agreement, New Age Engineering Solutions LLP provides the training for you and your employees in all phases of the manufacturing and installation operations. In addition to the training, New Age Engineering Solutions offers support for any problems or queries you may have during the production of installation stage.